It’s Fall Football Season and inspired by a Matt Ryan led Falcon loss this week, I wanted to share something about training in our business. This loss to Russel Wilson and the Seahawks, 26 to 24 was a tough one. After a close game like this, one cannot help but wonder what’s the difference between Matt Ryan and Russel Wilson, or me for that matter, when it comes to throwing a football. Sure we can measure completion rates and interceptions easily, but those are really a factor of intelligence and ball control. Measuring the later has always been reserved for scouts and coaches, but now everybody can get into the act.

If you haven’t heard already, Wilson Sporting Goods has just released an electronic football. You can read about it in various places, but I particularly like the discussion on CNET. The football provides all sorts of statistics to your phone after every throw. Here is what the article has to say:

“The warm-up and precision modes both measure throw velocity, distance, spin rate, and spiral efficiency, but the precision mode will also calculate a WX rating, which is Wilson’s version of ESPN’s QBR score to measure total quarterback performance. Seattle Seahawks quarterback Russell Wilson posted a WX rating of 1,553.5 (out of 1,600) when testing the ball.”

The author, Dan Graziano, goes on to say that he tried hard but he never broke 500 on the WX rating, but now he knows what he needs to learn to get off the couch and into the game.

Luckily, in our business, new technology can provide similar training and insights in a warehouse. I was recently asked, “What’s the value of training pickers?” As I travel around, study, and train pickers in warehouses all over the world, I’ve learned a few things. For example, experienced people pick faster than new people, not because they have smoother motions or work harder or are more engaged or make fewer mistakes, it is simply because they know techniques that save them time.

Furthermore, these methods are rarely taught by companies because most warehouses too often rely on OJT to train staff instead of formal training derived from detailed engineering observations of motion. Experienced pickers learn these usually on their own, but these techniques can be taught to pickers early on in their career. The savings can be significant.

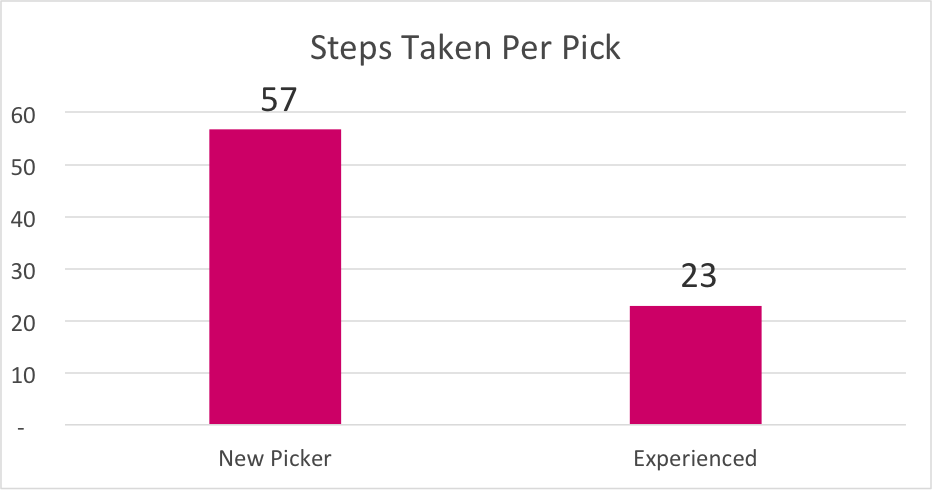

New technology can make the “technique gap” painfully obvious as well. As an informal in-house test, we provided FitBits (affordable test at $40/each) to an eCommerce fulfillment operation and instructed them to provide one to a new picker and one to a more experienced picker. Like the Wilson X, this device provides a myriad of statistics about your motion, however, the simple data of the number of steps per pick is all we needed. The devices were worn for an entire shift for picks provided randomly by the system. We recorded the number of picks each worker made at the end of the day and computed the following chart:

Walking is usually the largest consumer of picker time. Based on our experience, I knew the difference between how experienced pickers walk for a pick and how new pickers do it. For example, experienced pickers did things like drag totes with them as opposed to walking to the pick and then back to the tote. They skipped picks on the end of their zone, choosing to do those picks at the same time later in one trip. The FitBit data quantified what The Progress Group already knew.

I don’t think I will ever throw a football like Russel Wilson or Matt Ryan, but there are lots of new pickers in your warehouse this peak season that will be able to pick much more efficiently if you spend the time to discover the techniques that your full-timers have taught themselves and then formally teach those to everyone else. Formal training pays, and big. Trust me or invest in a couple of FitBits for your pickers in your warehouse.

As of September 8, 2020, Crimson & Co (formerly The Progress Group/TPG) has rebranded as Argon & Co following the successful merger with Argon Consulting in April 2018.